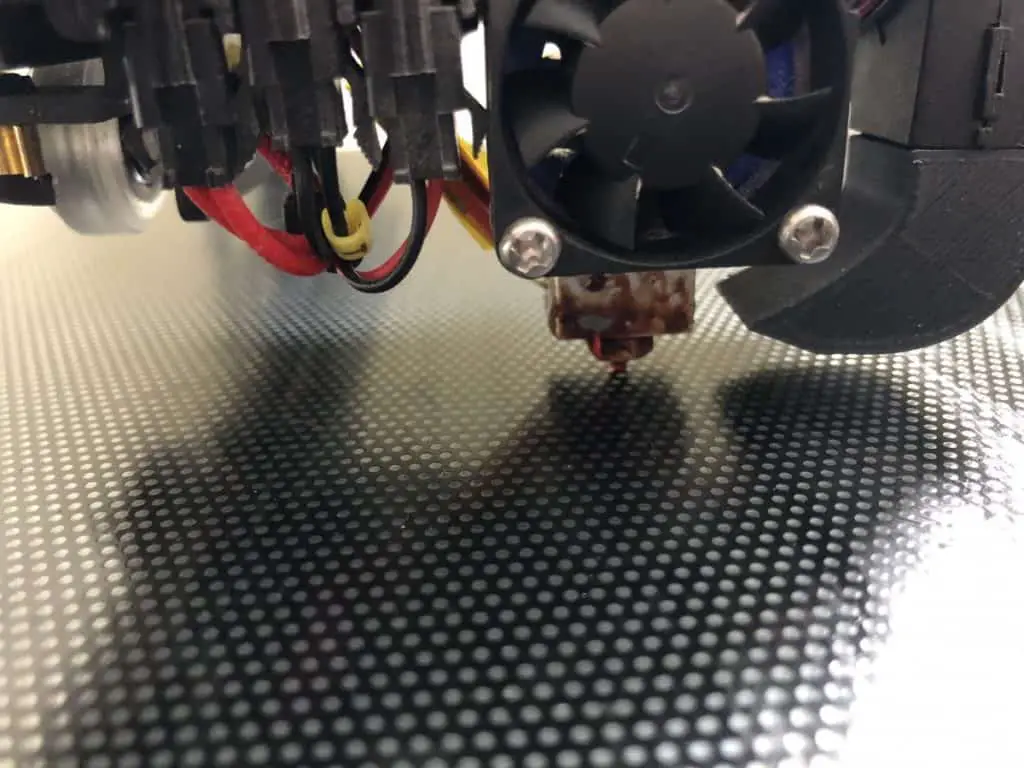

The hotend is the one of the most important parts of a 3D printer because it melts and transforms filament into printed parts. But you don’t put the hotend together correctly, the printer will suffer from blockages and jams. First, let’s look at exactly what the hot end is.

The hotend refers to five main parts of the extruder that heat up to melt filament and channel it through the nozzle. The hotend comprises a nozzle, heat block, heatbreak, heat sink, and pneumatic fitting.

The filament feeds through all these parts in the following order: pneumatic fitting, heat sink, heatbreak, heat block, and finally out the nozzle.

The pneumatic fitting insures that the PTFE tube is securely inserted into the hotend. The heat sink and heat break prevent heat from creeping through the extruder and the heat block melts the plastic just before it passes through the nozzle.

The cold end of an extruder comprises a stepper motor, gears, and springs, which all work together to feed filament through to the hotend to be melted.

You will require different hot-ends depending on which types of materials you plan to print with. For example, PLA can be melted sufficiently at around 170°C while soft metals have a melting temperature of around 230°C.

All-metal hotends are required when printing at high temperatures of 250°C or more. The PTFE tube does not pass through the heat break of an all-metal hotend, only the filament passes through the heat break and into the heat block area.

If you print with wood filament, you should choose a hotend with a nozzle size of at least 0.5mm to allow the strands of wood to pass through easier. Nozzles are interchangeable as long as you get the correct size thread. The Ender 3’s stock hotend has a nozzle with an M6 thread size and 0.4mm nozzle.

All-Metal Hotends

An all-metal hotend can reach higher temperatures because the PTFE tube does not go through the heat break. The PTFE tube is positioned just before the heat break and therefore doesn’t get hot enough to melt even though the heat block may be over 250°C.

The opening of an all-metal heat break has a 1.75mm hole for filament to pass through while PTFE heat breaks have larger openings for the PTFE tube to fit into.

So all-metal hotends make it possible to print materials like PC (Polycarbonate) which has a high melting temperature of around 270°C to 310°C. With PTFE-lined hotends, the tube will start to melt at about 250°C to 260°C.

The Micro Swiss all-metal Creality hotend kit is one of the most popular choices because it can operate up to 500°C. The heat break is made of Grade 5 Titanium Alloy, which prevents heat creep. Titanium is three times better than stainless steel at dissipating heat.

So all-metal hotends are the answer for printing materials with high melting temperatures, but you don’t need them if you only print with PLA and a few other basic plastics.

PTFE Lined Hotends

PTFE-lined hotends are the most common because they cost less while still being able to melt a wide variety of filaments all the way up to about 250°C. Although you probably won’t need to set it that high.

The PTFE tube pushes through the heat break up to the nozzle and can be damaged if you print at maximum temps. I recommend not going past 230°C.

Here are some materials that work well in this type of hotend.

| Material | Temperature |

|---|---|

| PLA | 180°C to 230°C |

| ABS | 210°C to 250°C |

| PETG | 220°C to 250°C |

| TPE, TPU, TPC | 210°C to 230°C |

| Nylon | 240°C to 260°C |

However, it’s important to note that if you’re going to be printing at temps of 250°C, you’ll need to replace the PTFE tube in a short amount of time as it will deteriorate.

So if you print with ABS, Nylon, or PETG, try starting off on the lower end of the temp ranges and avoid the maximum 250°C.

Although there’s such a wide variety of PLA filaments that you probably won’t need to print with anything else.

Are Hotends Interchangeable?

Many 3D printer hotends are interchangeable, but certainly not all. You need to check the compatibility to be sure that there won’t be any installation problems. Some hotends may be too big for your specific printer, for this reason, the manufacturer will always specify the printer compatibility.

How To Assemble A Hotend

E3D Hotend and Creality’s standard hotend assembly

- Start by screwing the nozzle into the heater block, but only 90%.

- Now screw the heat break all the way into the heat block.

- Screw the nozzle all the way against the heatbreak.

- E3D hotend: Screw the heat sink onto the heat break all the way.

- Standard Creality hotend: Slip the heat sink over the heat break and tighten the screw on it.

- Turn the pneumatic fitting 90% into the heat sink.

- Push the PTFE tube all the way through until it stops against the nozzle.

- Now turn the pneumatic fitting all the way into the heat sink for it to bite down and secure the tube.

What Makes A Good Hotend?

Micro Swiss, E3D, and Creality are three good quality hotends. What makes a good hotend is the precise machining that goes into it to make sure all the measurements are perfect. The “clones” at cheaper prices look the same but don’t perform well.

Good hotends are made of titanium, aluminum, and stainless steel because they work well to disperse heat and keep the heat break cool.

What Are Hotends Made Of?

The heat sink is usually made of aluminum. Standard nozzles are brass and higher quality nozzles are stainless steel. The heat break is made of stainless steel or titanium and the heat block is most commonly made with aluminum but also titanium sometimes.

How Long Do 3D Printer Hotends Last?

Hotends last thousands of hours, you can count on at least 5000 hours of printing time, and even then, you’ll probably only need to replace the nozzle and not the entire hotend. The reason they last so long is that there are no moving parts.

If you print ABS at high temps of 230°C to 250°C with a PTFE-lined hotend, you’ll need to replace the PTFE tube regularly.

What Does All-Metal Hotend Do?

An all-metal hotend allows you to print at temperatures higher than 260°C, like up to 500°C or more. This is because the PTFE tube doesn’t contact any of the hot parts of the hotend.

What Does A Heatbreak Do?

A heatbreak prevents the filament from being melted before it gets to the heating block. It prevents heat creep, which is when heat travels from the heat block and into the hotend where the filament is being pushed through. Heat creep causes blockages in the heat break.

The heatbreak is a metal cylinder that is cooled by a heat sink. The filament passes through the heatbreak before it gets to the heating block.

Related Articles

- Fix A Slipping Extruder – Details Inside!

- 3D Printer E-step Calibration (Step-by-Step Guide)

- 3D Printer Nozzles (Detailed Overview)

- Quick Guide to Change the Nozzle on a 3D Printer

In Summary

Since the hotend is so crucial in the printing process, make sure to assemble it perfectly to avoid blockages and jams. If you’re buying a complete hotend kit, spend the extra cash on quality brands.

Don’t bother upgrading to an all-metal hotend unless you plan on printing a lot of ABS, Nylon, and other high-melting-point materials. If you print with PLA, you only need the PTFE lined hotend.

The hotend will last forever with the nozzle being the only part you’ll have to replace after a few months if you use the printer every day. If you don’t use abrasive filaments, the nozzle will last even longer.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.

Good Article. I would also like to point out that I think the Gulfcoast Robotics all metal hotend seems to be under rated. I bought one a few months back and it has been a very good investment so far. I print a lot of ABS and an all metal hotend just seemed like the right thing to do.

Thanks for sharing, I will check them out.