3D pens block up just like 3D printers do because they share so much in common. Cleaning out your 3D pen helps prevent it from blocking, but it’s still possible. A partial block can go undetected and ruin the part you’re trying to print. So clean the pen out regularly to make sure it’s working optimally.

You can unblock a 3D pen by clearing it out with a needle or nozzle cleaning kit. Another method called “cold pull” involves heating the pen to the maximum temperature, cutting new filament at a 45° angle, and force-feeding into the pen. Then turn the heat down and pull the filament out.

By doing this, the filament sticks to the pieces of plastic inside the pen that are causing the blockage, which you then pull out along with the filament. I’ll cover that method later in the article because I believe you should try some other things first.

You can also clean out the nozzle with chemicals like acetone which will dissolve any plastic inside the nozzle. Here are all the methods with extra details and steps on how to perform them.

What To Do If Your 3D Pen Isn’t Working

Go through the steps below to determine if you have to unblock the pen or if something else is wrong.

3D Pen heats up but doesn’t extrude

- Make sure the pen is fully charged.

- Turn the speed of the pen to a faster setting and test it again.

- Confirm that the filament is loading into the gears at the top of the pen.

- If the filament isn’t loading or gets jammed shortly after entry, gently remove it and cut a fresh piece to load.

- Don’t pull it out with force. If it’s stuck, take the pen apart to clear it out without damaging the extrusion gears.

3D Pen doesn’t heat up

- First, make sure that the power cable is plugged into the outlet and pen correctly by confirming that the pen’s display is on.

- Test a different power cable if there’s no power going into the pen.

- Confirm that the feed button is working. It might be clogged with some dirt.

- If the heating starts but doesn’t get hot enough to heat the nozzle (if it’s metal), you might need to replace the nozzle.

After going through the steps above, move on to the next section to clean the pen out.

Clear The Pen Out With Cleaning Filament

Companies like eSUN offer cleaning filament that has adhesive properties. So when you feed it through the pen, it will pick up any bits of plastic and dirt it finds along the feeding tube and nozzle. Keep extruding the cleaning filament until it appears clear of debris.

The problem with this method is that it won’t work if the pen is completely blocked. But running some of this through your pen after every session will help keep it as clean as possible.

Temperatures between 150°C to 260°C will ensure that the pen is cleaned out properly.

This is how it looks on amazon.com: Cleaning Filament

Clean It Out With A Needle Or Nozzle Cleaning Kit

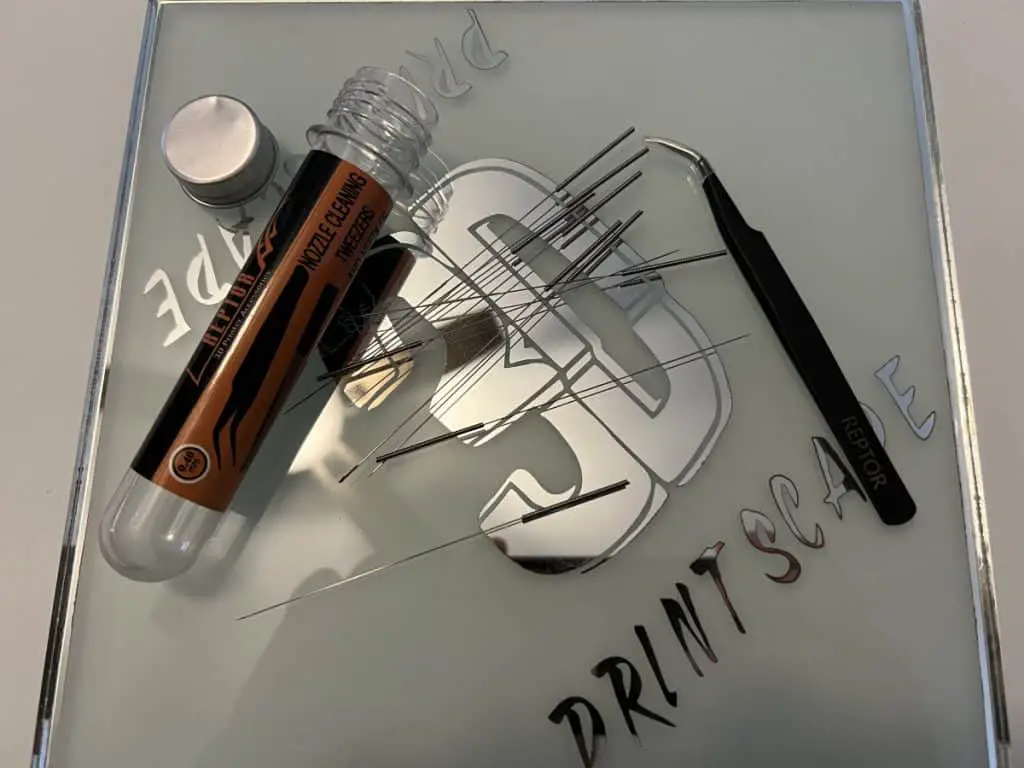

Nozzle cleaning kits are far better suited for unblocking nozzles than sewing needles are. This is because they make cleaning needles with strong, flexible stainless steel that won’t break easily. There are needles for cleaning out nozzles from 0.15mm to 0.5mm depending on what your pen has, probably 0.4mm.

The needles are very flexible to prevent them from breaking inside the nozzle and the tweezers make removing any extra filament from the nozzle’s tip safe.

Kits like these on amazon.com have all the needle sizes you need for any nozzle you have.

How To Remove The Nozzle From A 3D Pen

- Remove any filament in the pen. Use the reverse function if you have it.

- Heat the pen to operating temperature.

- Use a tool to turn the nozzle counterclockwise to remove it. (Don’t touch the nozzle)

- Switch the pen off.

- Let the nozzle cool down and clean it out with acetone. (Following the steps below)

- Heat the pen again and use the tool to screw the nozzle back on.

Don’t tighten the nozzle too much while it’s hot or you won’t be able to remove it next time.

How To Clean A 3D Pen Nozzle With Chemicals

Use chemicals like acetone to clean the nozzle out perfectly. Unscrew the nozzle from the pen and drop it into acetone to dissolve any unwanted debris.

- Unscrew the nozzle from the 3D pen. (Counterclockwise)

- Place the nozzle into a small, sealable container.

- Pour acetone over it until it’s submerged.

- Seal the container and leave the acetone to dissolve the plastic for 12 hours.

- Use latex gloves to remove the nozzle and then clean it off with a wire brush (available on Amazon).

- Rinse the nozzle off with water and leave it in the sun to dry. Or use a heat gun or hairdryer if you’re in a hurry.

Use a small container to save on the amount of acetone you’ll require. Also, use a metal or glass container, because the acetone will dissolve some plastic containers.

Perform A Cold Pull (Atomic pull)

A cold pull, or atomic pull, is a process where you fill the nozzle with melted plastic to bond with loose debris inside so that you can pull everything out. This method needs to be repeated to clean the nozzle out thoroughly.

- Heat the pen up to its maximum temperature and remove any filament you can.

- Cut a new piece of filament at a 45° angle and load it into the back of the pen.

- Keep feeding it through the pen until you see it dripping out the nozzle.

- Now allow the pen to cool down as while still pushing on the filament. This is to make sure the tube and nozzle are completely filled.

- The filament will stop coming out of the nozzle at around 60 °C.

- Now heat the pen up while gently pulling the filament out.

- This should get loose plastic to stick to the filament to pull out.

Repeat this process until you see that there’s no more debris on the new filament.

How To Prevent A 3D Pen From Blocking

- Use clean, high-quality filament.

- Clean old filament off with a damp cloth to prevent dust from entering the pen.

- Don’t use low-quality filaments because their thickness is inconsistent and they may have extra unwanted particles inside.

Why 3D Pens Smoke

Mostly, 3D pens smoke when you heat them up with left over filament in the nozzle. To avoid this, clean your pen after every use. 3D pens can also smoke when the temperature is set too high. But don’t reduce the temp too much or the plastic will come out thick and slow. PLA works well at around 190°C and ABS at around 220°C.

How Hot A 3D Pen Gets

The nozzle on some 3D pens can reach up to 250°C. The filament comes out of the pen between 175°C to 245°C and the housing of the pen should only warm up slightly so that you can still hold it comfortably.

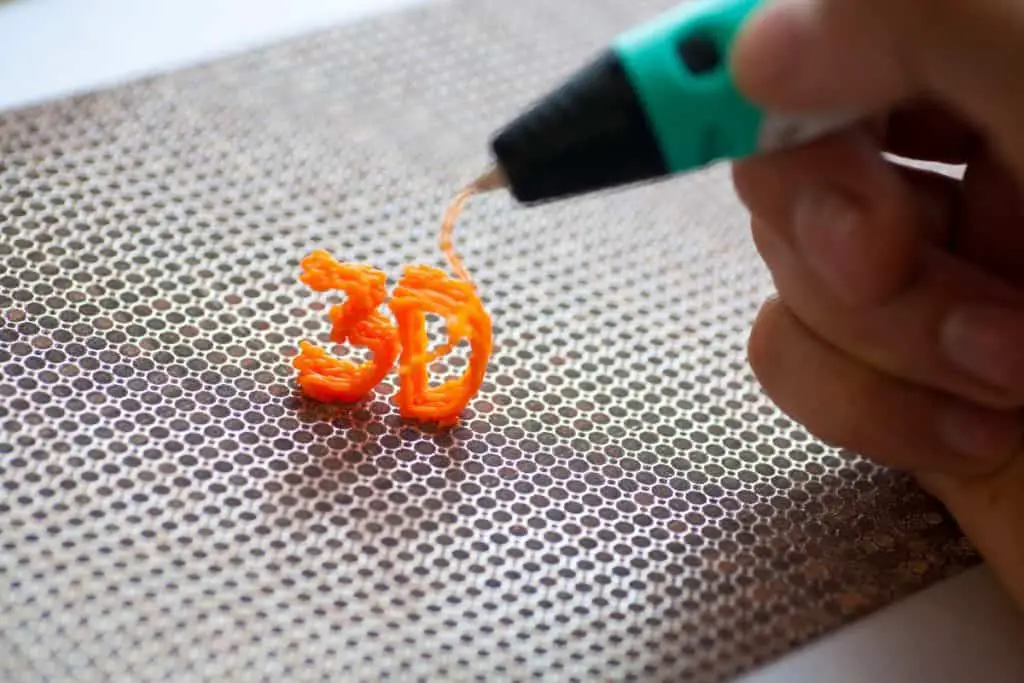

Why The Filament Could Come Out Stringy

If the temperature of the pen is set too high, the filament could come out stringy. Reduce the temperature by 5°C, test the pen, and then reduce the temp again if the problem persists. Don’t go below 175°C with PLA or below 200°C with ABS or the pen might have extrusion problems.

How Long A 3D Pen Should Last

3D pens last six to twelve months before showing signs of problems. Sometimes, you can extend the life of the pen with regular cleaning, but most of the time, the parts wear down and fail. This applies to most 3D pens on the market today, all of which are under $100, so you can expect to pay that once a year if you use the pen often. If you only use it once or twice a month, it could last two to three years, but obviously, it will differ for every case.

Related Articles

- 3D Printer vs 3D Pen: Whats right for you?

- Does PLA Filament Need To Be Dried Before Use?

- How To Tell if PLA Filament Has Gone Bad

- PLA vs PLA+ – What’s the Difference?

- All About 3D Printer Plastic

In Summary

Use nozzle cleaning needles to loosen the plastic inside the nozzle. Perform a cold pull to unblock the pen or just feed cleaning filament through if it’s only partially blocked. Use chemicals like acetone to soak the nozzle and dissolve the tiniest pieces of plastic inside.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.