3D printing is one of the most promising technologies we have today because of how it can basically use different types of polymers to construct something out of what seemed to be nothing. In that sense, 3D printing requires suitable polymers or thermoplastics that can be melted and are quite sturdy once they have hardened after printing. So, does that mean that you can 3D print using UHMWPE?

It is theoretically possible to 3D print UHMWPE, but everything is still experimental now. It would be extremely difficult or even close to impossible to 3D print it through the process of injection or extrusion because of the long molecular chains and the low melting point that UHMWPE has.

Like a lot of the different polymers and thermoplastics that we have today, there is a good reason to believe that we can one day 3D print using UHMWPE, which is believed to be a good material to use due to how strong and sturdy it is. However, the thing you need to know is that we are still in the experimental stage today, as there are still challenges regarding 3D printing UHMWPE.

What is UHMWPE?

When it comes to 3D printing, the one material that stands out among all of the others is thermoplastic. The reason is that polymers or thermoplastics can easily be melted and then put together to form the 3D-printed model using a process that injects small particles of melted plastic together to form the final product.

There are plenty of different types of thermoplastics used in 3D printing, and all of them have their own advantages and disadvantages. One type of thermoplastic that is becoming quite popular for manufacturing is ultra-high molecular weight polyethylene or UHMWPE. But what exactly is UHMWPE?

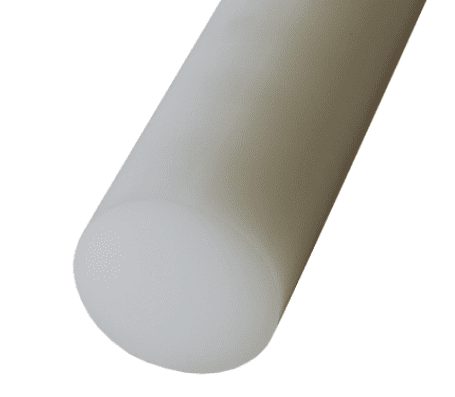

UHMWPE is basically another type of thermoplastic polyethylene that has extremely long molecular chains that are somewhere between 3.5 and 7.5 million amu. Because of how long its molecular chains are, it is a material that is actually very tough and is nearly as strong as carbon fiber in terms of its overall toughness.

In fact, UHMWPE has the highest impact strength out of all of the thermoplastics we have in the world today and has an ultimate strength that is on par with Kevlar and slightly lower than carbon fiber. UHMWPE also has a low specific gravity that makes it stronger than all of the other types of fibers in terms of weight. It is even 15 times stronger than steel when it comes to its strength-to-weight ratio. This makes it an ideal material to use when constructing different products using plastic.

But the problem with UHMWPE is that it does come with a lower melting point and has a reduced maximum operating temperature. This basically means that it will melt easier than other types of polymers. In fact, it has a melting point of just 130 degrees Celsius, which is much lower than the melting points of other strong fibers such as Kevlar, which has a melting point of 500 degrees.

However, even though UHMWPE does have a lower melting point, it still is advantageous to use in other instances because of how strong this polymer is. Even its low melting point can be seen as an advantage in some instances. Because of how easy it is to melt UHMWPE, it will be easier and cleaner to recycle because there is no need to use chemical processes that create unwanted byproducts just to recycle this type of plastic.

In terms of its physical properties, UHMWPE has a higher fracture toughness compared to carbon fibers. This means that there are plenty of practical uses for it in a lot of different industries that can make use of its fracture toughness. Of course, because of how tough it is, it might be promising to use UHMWPE to produce durable 3D-printed models and products.

Can you 3D print UHMWPE?

Now that you have a quick idea of what UHMWPE is let us now look at it from a different perspective. As tough as UHMWPE, can you 3D print using this material?

The thing you need to know about UHMWPE is that it has a very low melting point that is around 130 degrees Celsius. At first, it doesn’t seem like that hurts its prospects of being used for 3D printing. However, the fact that it has a low melting point is what makes it difficult to use in conventional injection or extrusion 3D printing.

The reason is that 3D printers that extrude thermoplastic filaments usually do so at temperatures that are 200 degrees or more. This means that when you use UHMWPE in such a process, it will be very difficult to extrude it at high temperatures that will keep it in a melted state properly. In that sense, you won’t be able to properly form a 3D model using melted UHMWPE.

Then again, it is still theoretically possible to 3D print using UHMWPE. While it might be extremely difficult to do so using the conventional 3D printers that we have today, some experiments have been conducted to see whether or not UHMWPE can be 3D printed using other means.

In an experiment, UHMWPE was successfully embedded in PLA 3D printing by etching the UHMWPE fibers with chromic acid. However, the experiments had to manually lay the UHMWPE, which can be a hectic process due to the lack of automated fiber-laying techniques that can be used in 3D printing today.

Still, the experiment made it possible and was able to successfully 3D print using UHMWPE using a PLA matrix. However, the fact of the matter is that there needed to be certain variables changed, such as the extrusion temperature, which was lowered to values under 200 degrees to make sure that the UHMWPE mixture won’t end up melting too much and causing its molecular structure to alter.

That said, everything about 3D printing using UHMWPE is still experimental today. So, while it might be possible to 3D print UHMWPE in a theoretical sense, we still haven’t reached a point where doing so can be done on a commercial level.

Related Articles

- Can Nanoparticles Be 3D Printed?

- Will 3d Printing Replace Injection Molding?

- What Shapes Cannot Be 3d Printed? – Details Inside!

- Will 3d Printing Replace Machining? (We Find Out)

- Do 3D Printers Use a Lot of Power? (The Numbers Inside)

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.