A critical step in familiarizing yourself with SLA printers (or stereolithography) is learning how to operate the printers safely. While very useful in creating 3D prints and models with intricate features, there are hazards such as a laser, electricity, fumes and hot materials involved in the use of an SLA printer. You have to protect your skin, eyes, and respiratory system.

How can you operate SLA printers safely? For safe operation of SLA printers, be sure to:

- Place the printer in a well-ventilated area with limited occupancy

- Always wear protective clothing in accordance with the manufacturer’s safety

- Consult Saftey Data Sheet (SDS)

- Place the printer as close as you can to the room’s ventilation exhaust grille if one is available

- Wash hands thoroughly after working with SLA printers

- Never bring food and drinks to or handle cosmetics and contact lenses in your designated 3D printing area

Although SLA printers sound dangerous, they are quite safe when they are operated safely. Here we will thoroughly address any safety concerns related to the operation of SLA printers, including whether SLA printers should be used to produce objects that hold food.

What Is SLA Printing?

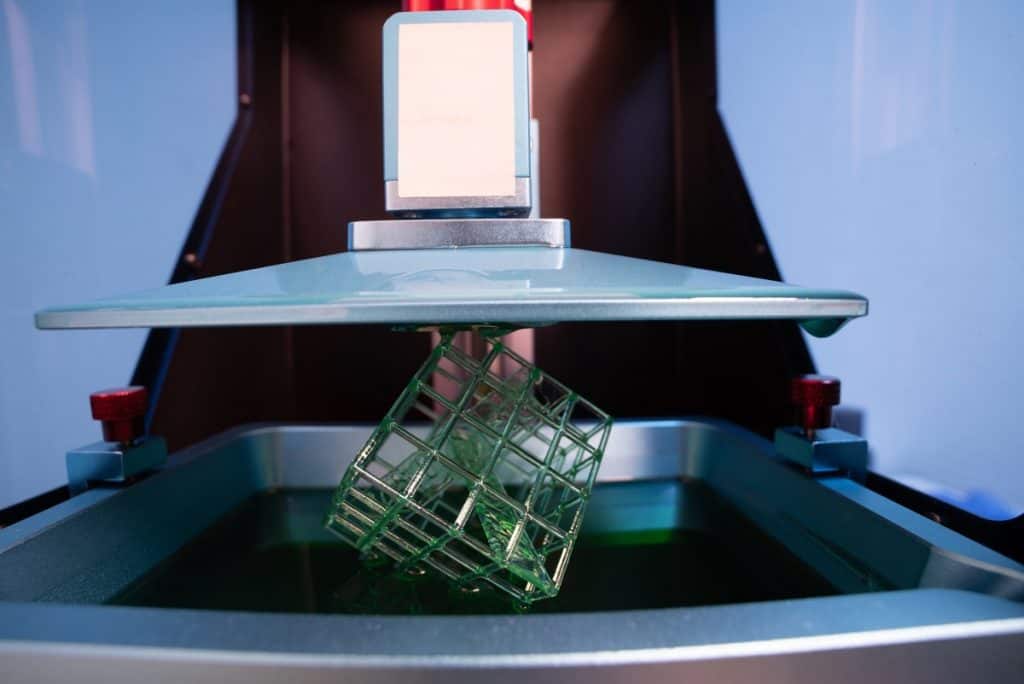

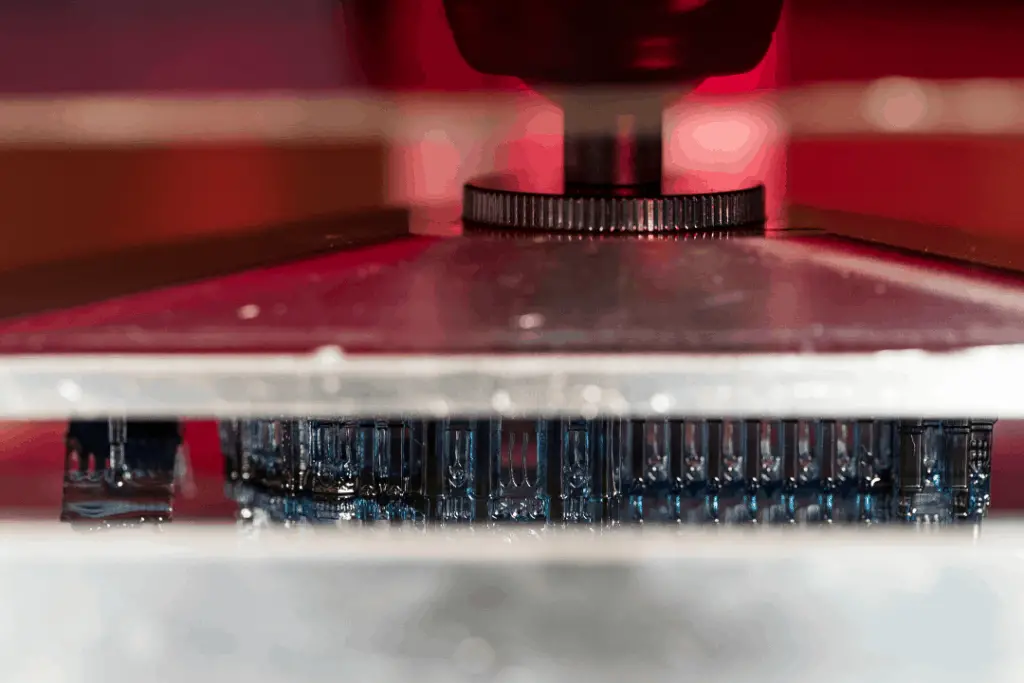

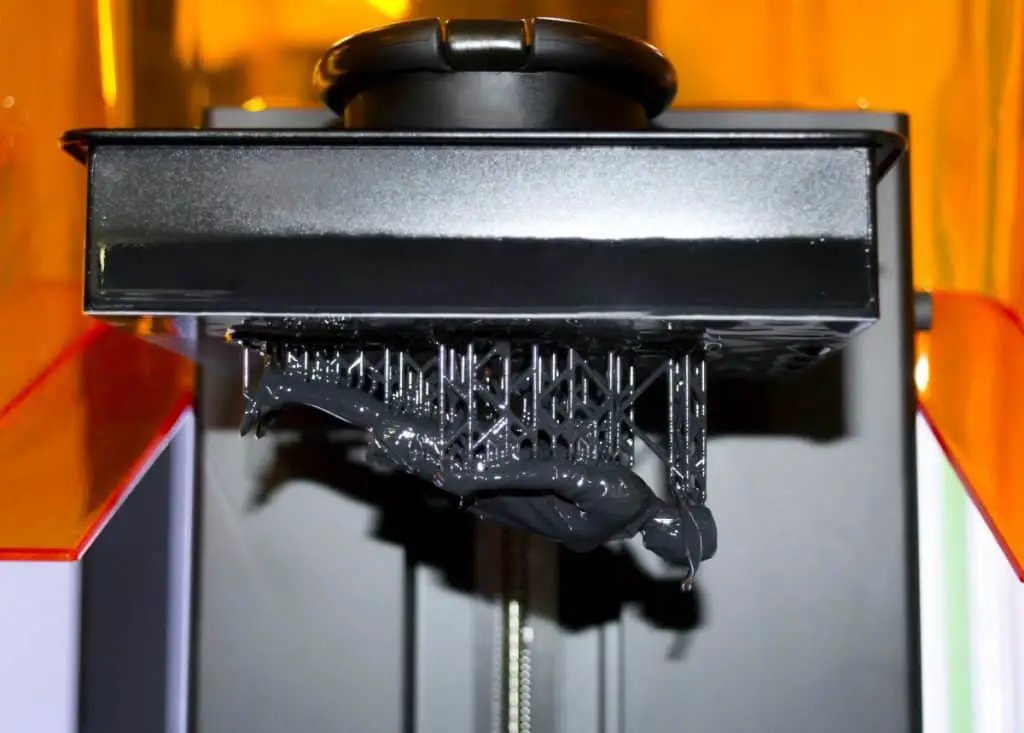

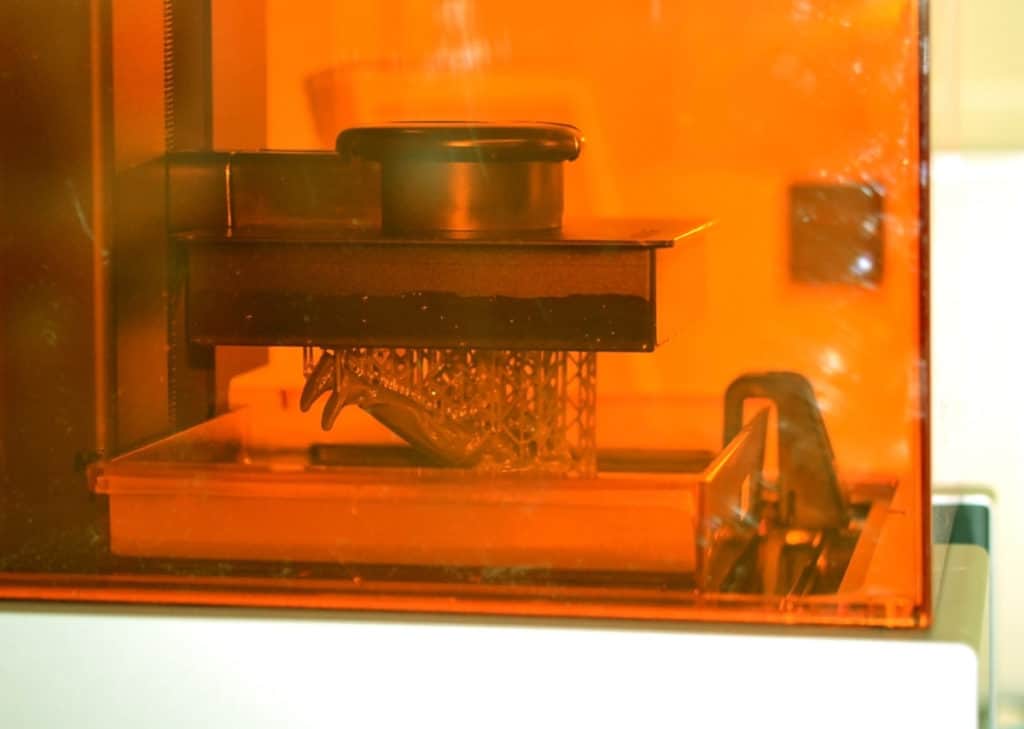

Stereolithography printing, abbreviated as SLA, is a unique approach to 3D printing. The process involves the use of a laser to “cure,” or build and dry an object that is composed of photopolymer resin.

This method represents exciting inroads in the production of small, intricate objects through 3D printing.

Before you get started, you will need to learn about how the safety requirements of these machines differ from what you may see with other methods of 3D printing.

Here is a video of an object being printed with an SLA printer.

Why Are Uncured Printing Resins Dangerous?

One study exploring the toxicity of the photopolymer resin on Zebrafish embryos found that 100% of the embryos exposed to resin-based SLA printed parts were dead within 7 days.

However, a UV-curing process, or a process in which the printed object was exposed to UV light, produced an object that was measurably less toxic.

The key takeaway: Allowing the object you have printed to be exposed to UV light is an important safety procedure to follow in SLA printing.

Personal Protective Equipment

SLA printers come with more advanced safety requirements than your traditional Fused Deposition Modeling (FDM), or 3D, printers.

When using FDM printers, you have to make sure that you don’t burn yourself, but with SLA printers, you also have to avoid exposure to dangerous chemicals found in the uncured printing resins.

Before you do anything else, make sure to buy protective gear:

- Gloves: Disposable nitrile gloves such as the ones found here will work to protect your hands.

- Chemical splash goggles: Protect your eyes in case resins happen to splash into your eyes, with goggles like these.

- Clothing: Long-sleeved shirt, long pants. Preferably items you wouldn’t mind having to throw out.

- Shoes or boots: Protective footwear with closed-toes.

It is also important to view the Safety Data Sheet(SDS) for photoreactive resins to properly outfit yourself for safe use of your SLA printer.

Put A Tray Underneath Your Printer

In order to protect the tabletop that your SLA Printer sits on, it is recommended that you place your SLA Printer on top of a tray or container.

One tray you can place your SLA Printer on top of is this large plastic dog crate tray that can be repurposed. This way, you will be protected from a spill of uncured resins. Spills may occur when you are trying to remove the printed work from the print platform.

Proper Ventilation

SLA printers should be placed in a well-ventilated area. 3D printers have been shown to give off airborne ultrafine particles (UFP) and volatile organic compounds (VOCs) at very low levels in some cases.

The safety data sheet (SDS) for Anycubic UV-curable resin states that to ensure personal protection from harmful chemicals, you should keep the area where your printer is located well-ventilated.

Although unlikely, you may need to wear a respiratory protection mask, particularly if you have prior respiratory issues.

Airborne particles are potentially less of a concern with SLA printers than they are with FDM printers. Still, you are encouraged to take every necessary step to avoid the accidental intake of potentially harmful substances such as those found in uncured photopolymer resins.

Resin Safety

The handling and safe disposal of photopolymer resins are the most critical steps to follow. Handling resins safely will prevent you from accruing toxic substances over time.

Proper disposal is also necessary to prevent harming wildlife. Flushing chemicals down the drain is a good way to get rid of them fast, but it is not the most responsible solution. Proper disposal methods will be discussed below.

Handling

The uncured resins used in SLA printing are not chemically inert (or chemically inactive). They can be harmful if not handled properly.

As was mentioned above, you should also wear personal protection equipment, including nitrile gloves and chemical splash goggles, when you are handling the photopolymer resins used in SLA printing.

In the event that you have spilled some resin, clean it up using warm soapy water. Although 99% Isopropyl Alcohol is the recommended cleaning agent, it can also remove the varnish from some surfaces.

Safe Use of Photopolymer Resins in SLA Printing

Here are some guidelines for safely operating with the photopolymer resins used in SLA printing:

- Avoid adding more resin to the vat mid-print

- Instead, take the vat out between print jobs and fill the entire vat.

- If you add resin to the vat while it is attached to the printer, you run the risk of spilling resin into the hard-to-get-at components of the printer, creating a gooey mess that will be difficult to clean.

- Avoid trying to recycle resin

- Otherwise, you run the risk of causing cross-contamination when you try to transfer resins from the vat back to its storage container. The best practice is just to avoid this.

- If you feel that you must recycle resin because you go through multiple colors in one day, do this:

- Find a fine mesh screen like the ones you would use in cooking. It needs to be made of stainless steel to avoid causing a reaction.

- Run the uncured resin through the screen to remove any bits of the cured resin

Proper Storage Of SLA Printing Resins

In order to prevent the cross-contamination of different resins and to keep the resins in a safe, operable condition, it is critical that you know how to properly store printing resins.

Here are some guidelines for safely storing 3D printing resins, according to the Safety Data Sheet(SDS):

- Make sure that containers are airtight and stored in a cool and dry place that will prevent electrostatic charges from building up

- Avoid storing the bottles in places where they will be exposed to sunlight

- Do not store near strong acids, oxides or highly alkaline substances

How To Properly Dispose Of SLA Printing Resins

If you have removed the uncured photopolymer resin from your printed work or from your equipment, you will need to know how to safely dispose of it. Never flush uncured photopolymer resins down a drain.

The best way to dispose of uncured SLA printing resins is to search for local hazardous waste management facilities by using this EPA directory.

Otherwise, you can keep used uncured resin within a container full of isopropyl alcohol. After letting the isopropyl alcohol and resin mixture evaporate in the sun or another source of UV light, you will be left with a layer of hardened resin.

The hardened resin can then be scraped off into the trash or down the drain. For the resin to be cured, it will have to have been exposed to UV light.

Cleaning Uncured UV Printer Resins

At some point, you will need to clean off uncured UV resins from the finished product and from the equipment. The “curing” process mentioned here involves coatings of resin drying onto the print or finished product via a photochemical reaction.

UV-curable inks represent an alternative to conventional solvent-based products dried by heat and air, causing solvents to oxidize and evaporate.

These instructions will refer to the removal of uncured resins in anycubic photon systems, though the general procedures will remain much the same regardless of which specific resin printing system you are using.

Getting Started

- You will need to use some type of solvent to help you remove the uncured resin.

- The most popular choice among users is 99% isopropyl alcohol.

10 Steps to Cleaning Uncured Printer Resins

| Step Number | Description |

|---|---|

| Step 1 | Put on protective equipment, including gloves and chemical splash goggles. |

| Step 2 | Make sure that the machine has been turned off. |

| Step 3 | Open the lid on the machine. On the anycubic photon system, this can be accomplished by pressing on the bottom of the lid near the base of the printer and lifting the lid up. |

| Step 4 | Remove equipment to clean off the printed work. Most every system is the same in how you do this. The AnyCubic system has a knob at the top; you can turn to free the printing components from the machine. You will find the printed piece of work attached to the base of the print platform |

| Step 5 | Bring the entire platform to a finishing station located near the machine to minimize potential dripping of uncured resins. Your finishing station can simply be a plastic container which you have filled with the 99% isopropyl alcohol |

| Step 6 | Use a sharp metal scraper such as this one to carefully remove the finished work from the print platform. This should be a dedicated scraper that you use solely for this purpose since it will accumulate toxic uncured resins on the blade |

| Step 7 | Drop the printed work into a plastic container filled with 99% isopropyl alcohol. |

| Step 8 | Shake the printed workaround in the solution to remove the unwanted buildup of uncured UV resin. You may also consider using a toothbrush to remove spots of resin buildup on the printed work |

| Step 9 | To finish, you will transfer the printed work to either a UV curing station or sunlight for a few minutes to finish the curing process |

| Step 10 | Never flush the 99% isopropyl alcohol solution down a drain. To properly dispose of this solution, take it to a local disposal center that deals with harmful substances like paint and chemicals. Or you can allow the 99% isopropyl alcohol to evaporate. But keep in mind that this will leave behind a layer of UV resin in the containers. |

First Aid Measures For 3D Printer Resins

Here are some steps to take in the event that you have been exposed to potentially harmful uncured printing resins. if you have any questions on this, please contact a qualified medical professional. I am a hobbyist that is sharing information, not a doctor.

Skin Exposure

- Wash the skin with soap and water

- Remove any contaminated clothing and clean before reuse

Eye Exposure

- Hold eyes open and continuously was with a gentle stream of clean water for at least 15 minutes

Inhalation

- If exposed to excessive vapors, leave the area and seek fresh air. Seek medical attention if further irritation develops.

Can I Make Food-Safe Objects With SLA Printers?

In order to be deemed “food grade,” the material must be either safe for human consumption or not have toxic effects if it comes into contact with food. Food contact surfaces also need to hold up over time so that they do not potentially have toxic effects as they break down.

Here we will answer the question of whether you can use SLA printers to make objects such as bowls that will hold food and not transfer the toxic effects of uncured resins to the food items they hold.

In order to be safe for holding food, these objects will also have to:

- Be resistant to the chipping away of the surface causing the object to have sharp edges

- Be corrosion-resistant

- Be able to withstand repeated washings without breaking down

Here are some common issues that can make 3D printed objects unsafe for holding foods:

| The Problem | The Solution |

|---|---|

| Bacterial buildup: Objects molded in 3D printers may have small little pots and nooks and crannies in the structure of the object that harbors harmful bacteria | Use a food-safe coating on the object |

| Dishwasher Breaking Apart Molds: Most of the printing materials you use might become deformed at the high temperatures present in a dishwasher due to their low heat deflection temperature | Check to see that there are specific instructions regarding the washing temperatures of the materials you are using. When in doubt, clean objects by hand to be safe |

| Cross-contamination of printing materials: It is possible that some of the resins you have used in your printer are more toxic than others and you may inadvertently include remnants of these resins in your object that is supposed to be food-safe | Always make sure to clean the inner components of your printing components thoroughly between different uses. Use 99% isopropyl alcohol to clean printer components such as the printing platform. |

| Chemicals leaching into food: Over time toxic chemicals may migrate from the 3D printed object to the food it is holding if the food contact time is long | Try to limit the period of time that food is sitting in the container just to be safe |

| Toxicity Of SLA Resins: The toxicity of the resins used in SLA printing makes resin printing technically not safe even though SLA printing is known for producing objects with a smooth finish. | A way that you can potentially employ the advantages of SLA printing to create objects that will eventually hold food will be discussed further directly below. |

SLA printings should not come in direct contact with food. However, there is a way to put a protective food safe coating on the object. Keep in mind that this coating may not be able to stand the test of time.

Using Ceramics With SLA Printing Technology to Create Food-Safe Objects

You can utilize SLA Printing technology to produce ceramic parts. This way, your end product food-safe.

- First 3D Print Your Object

- Then fire the parts in a kiln to create an object that is stronger and heat resistant

- This process should make the 3D printed part more resistant to chemicals

- Then apply a safe food glazing

- Food-safe glazings include this one from Duncan

Summing Up

There are definite risks associated with using an SLA printer. But all of them are avoidable if you take the right precautions. It starts with the place you house your printer – make sure it is well-ventilated. Wearing equipment that protects your hands, skin, and eyes – every time you use your printer is the best way to ensure you don’t injure yourself during production.

And, of course, only use your printer according to the manufacturer’s guidelines.

An SLA printer is a cool tool to have for so many reasons. And its dangers are far outweighed by its uses, as long as you are diligent and practice safe usage every time you print.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.