Humidity often affects the 3D printing process, and most of the time, the effects are adverse. However, suppose you are using resin to print up some objects. In that case, you’ll need to consider how humidity might affect the liquid resin in the tank or vat, the process of resin 3D printing, and the effect of moisture on resin prints.

Moderate humidity does not affect the resin 3D printing process. However, the liquid resin is hygroscopic, so it can absorb some moisture if exposed to high humidity for a long time. Also, prolonged exposure to high humidity can affect uncured resin prints.

3D resins manufactured by various companies are not identical. Some companies like Formlabs do not disclose the formulas of their resins, so the only way to know their resistance to humidity is by testing the materials. Read on as I explain if and how humidity affects resin 3D printing.

How Does Humidity Affect Resin 3D Printing?

Humidity does not affect the resin 3D printing process. However, it will affect the quality of the resin in your vat. Also, humidity does not affect different resins identically.

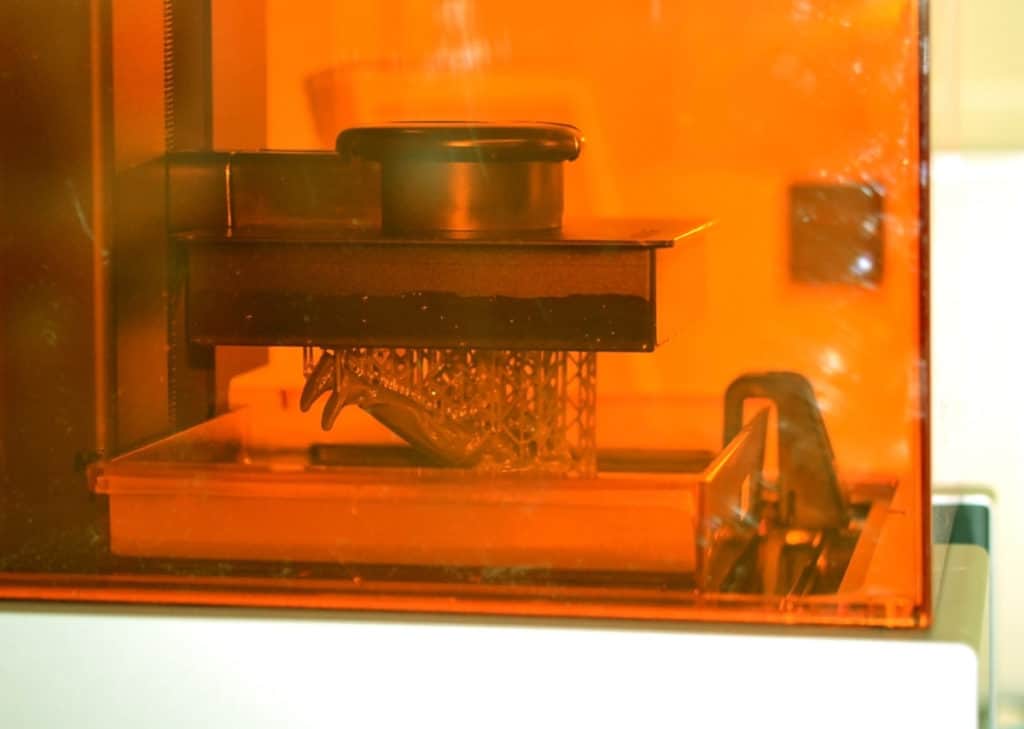

First, let me address the effects of humidity on the 3D printing processes for resin, SLA, DLP, or LCD. All three methods use UV light to photo-polymerize the resin.

Suppose you use fresh resin from a new bottle. In this case, it is fair to think that the resin has not come in contact with unusual humidity. Under these circumstances, you should have no printing issue. The UV, build plate, and other 3D resin printing components are not vulnerable to moisture. So, if your liquid resin is fresh, you won’t have any issues related to water.

However, the relative humidity in your print area should not be absurdly high. Even if the moisture in your room is unusually intense, it will affect the resin in the tank, not the printing process. If the resin in the tank is adversely affected by humidity, it will create issues while printing.

Still, the issues are not universal. For instance, if your printer has an enclosure, the humidity will affect your print less. Besides, the resin quality and composition determine how resistant or vulnerable it is to moisture.

So, let’s look at some examples of how humidity can affect your liquid resin and the 3D printing process:

Formlabs’ Nylon 12 Is Vulnerable to Humidity

According to Formlabs, the Nylon 12 resin needs relative humidity around the 3D printer to be less than 50%. If the ambient moisture in your room, studio, or around the printer is higher than 50%, the Nylon 12 resin will lead to failed prints, underdosing, and clumping.

Low humidity poses absolutely no threat to 3D resins. Also, 3D SLA, DLP, or LCD printers do not use heat, so the average room temperatures you have are not an issue for the resin.

You can always use an enclosure or dehumidifier to isolate your environment or dry it out, which will prevent print failures.

3D Systems’ Accura ClearVue Is Humidity Resistant

So, let’s see an example of when humidity won’t affect your resin’s quality and chances of print success.

Accura ClearVue (SLA) is a transparent resin from 3D Systems. According to the company’s datasheet, the resin has excellent resistance to humidity and moisture. Therefore, the relative humidity in your 3D printing studio or room is not a concern, even if it exceeds 50%.

Resione W90B Is Water-Washable, With a Caveat

Some resins are water-washable, but that doesn’t necessarily mean humidity won’t affect them.

You are probably familiar with water-washable resins, like the Resione W90B. Interestingly, you can wash the 3D prints made with this resin before curing, but the company recommends not to place the W90B models in a humid environment or water for a long time.

In addition, printing with a water-washable resin in a humid environment may decrease the integrity of your print, so you’ll need to follow the 50% humidity or less rule when using them.

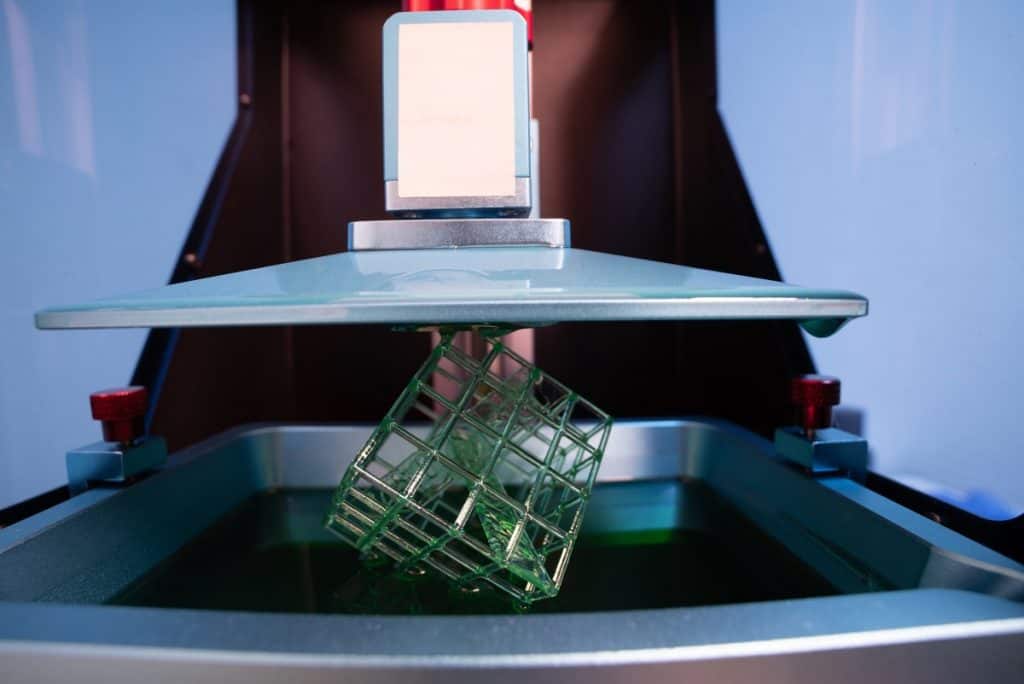

Does Humidity Affect 3D Resin in the Tank or Vat?

Humidity affects 3D resin in the tank or vat. Also, humidity can affect stored resin if the container is not airtight and the material is already contaminated. Hence, most companies advise against keeping unused resin in the vat if you won’t use it within 24 hours.

Although not all resin formulas and ingredients are the same, almost all resin for 3D printing has some sensitivity to moisture. Here are the commonalities between most resins that make them vulnerable to water:

- All 3D resins are liquid.

- Most 3D resins comprise polymers or plastics.

- The liquid form and plastics make the resins hygroscopic.

- Thus, the resin in the vat will absorb some moisture when the humidity is high.

Formlabs, Resione, Zortrax, and other brands advise users not to keep the excess resin in the tank or vat for longer than 24 hours. Also, you should not pour the unused resin back into the original bottle because the material in the vat may already be contaminated.

Use another container to store the unused resin and filter the liquid to keep the partially cured clumpy pieces out. You can still use this resin, but it might be more challenging to work with than fresh-out-of-the-bottle liquids.

Here are three reasons why you should not keep the unused resin in the tank or vat:

- Exposure to humidity can lead the resin to absorb moisture, and you may have printing issues.

- The uncured resin in the vat may gradually solidify further, thus making a mess in the tank.

- Some untreated resin may accidentally harden or partially cure due to exposure to UV light.

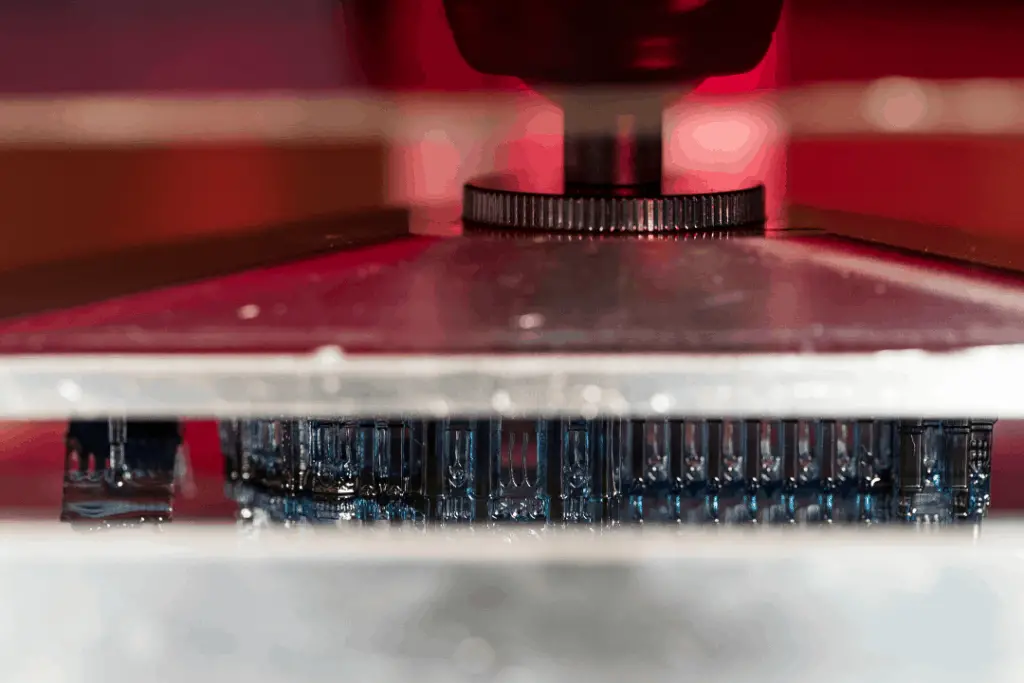

Does Humidity Affect 3D Resin Prints?

Humidity affects 3D resin prints if they are left on the build plate or elsewhere before curing. However, such effects are minimal and often unnoticeable. If a 3D resin print is cured, humidity does not impact the model, irrespective of how wet it is.

3D resins have a solid finish after printing and completely curing. Thus, the cured material will not absorb moisture from relative humidity, even if it is abnormally high.

Also, the curing process itself can make a 3D resin print more resistant to moisture, even water. It is possible to create waterproof models with resin 3D printing.

However, heat, room temperature, and humidity can affect the mechanical properties of 3D resin prints. Generally, the moisture will impact your 3D printed objects in the following respects:

- Tensile strength

- Elasticity

- Toughness

- Ductility

- Resilience

However, science says that humidity will affect each print differently depending on your resin. A team of researchers studied the mechanical properties of 12 commercial-grade resins at the Laboratory of Bio-Inspired Nanomechanics of the Polytechnic University of Turin. The purpose of the study was to test the variances of different resins per the recommended curing processes.

The report inferred that the variations between the common measurements and actual findings might be due to unaccounted variables, such as lighting conditions and humidity during storage. However, these differences are not that significant for hobbyists and beginners.

Related Articles

- Why Is 3D Printing Resin So Expensive?

- Resin vs Filament Cost Comparison

- How Long Can You Leave Resin in a 3D Printer?

- How To Cure UV Resin Without UV Light

- Why Wash and Cure Resin Prints?

Conclusion

High humidity affects the resin used in 3D printing, especially when the liquid is in the tank, vat, or reservoir. Also, do not expose any 3D resins to high humidity or moisture during storage and handling since water can introduce print errors and weaken your 3D prints.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.