PETG has made its mark as the run-to printing material for hobbyists and experts in the past few years. It’s resilient, durable, and versatile. However, even the most popular filament is prone to warping at high temperatures.

PETG starts to warp at a temperature of 170° C (338° F). As the warping happens, you’ll notice the edges of the print curling upwards from the print bed. PETG typically prints best between 90 and 110° C (194 and 230° F).

This article will explain what warping is and how it happens at that temperature. I’ll also discuss a few tricks to prevent your PETG print from warping.

Why Does Warping Happen?

When a portion of your printed object begins to curl upwards, you have a warped 3D print on your hands.

Warping happens due to significant temperature variations between extruded plastic layers. Uneven cooling causes stress inside the model, and as the temperature disparity increases, lower layers begin to lift upwards, resulting in a warp.

Filaments used in 3D printing are typically thermoplastics, which can melt, cool, and retain mechanical qualities. So, to use them, we need a bit of heat – which is where warping comes in.

Thermoplastics expand as they heat up, then contract as they cool and return to a solid state. If you use a heated bed, you may be able to mentally divide your print into three segments: the warm layers on the print bed, the cool layers in the middle, and the hottest layers near the nozzle.

As some layers cool while others are still hot, there’s a lot of pressure between each print segment. This pressure is the cause of 3D print warping: colder layers contract and tug on hotter, softer layers.

If you use a heated bed and the foundation layers are warmer than the middle layers, the 3D printed item will curl upwards and stop sticking to the plate. Warping might appear after a significant percentage of the print job has already been completed, destroying an otherwise great print.

The best way to prevent warping is to keep the entire 3D-printed object at the same temperature throughout the print job. However, this is practically impossible. Still, we can do a few things to prevent warping and stabilize a print’s cooling rate.

How To Prevent Warping and Save Your Prints

Regulate the Temperature

The most critical aspect in avoiding warping is temperature, not only of the filament but also the bed and surrounding air. The ideal temperature for PETG is between 90 and 110° C (194 and 230° F). However, every PETG filament is different, so look at the specs for the brand and formula. You’ll find instructions on either the maker’s website or your filament spool.

You can also use some tricks to regulate the temperature during your prints.

Here are some pointers for maintaining ideal temperature conditions:

- Use a heated bed. A warm bed evenly distributes the temperature in the model and aids in bed adhesion. Typically, the filament manufacturer specifies the required bed temperature.

- Use an enclosed print chamber. An enclosure helps to keep the ambient temperature consistent during the printing process.

- Keep the model’s surroundings enclosed. You can do this by closing the windows and doors. Isolating the area will prevent any chilly air from coming into contact with the 3D print.

- Adjust the cooling. Reducing the cooling rate is challenging since you still need to cool the filament for better adhesion and less stringing. However, turning off or slowing down the fans, at least for the first layers, may assist in balancing out temperatures sufficiently to keep your object flat on the build plate.

Use Adhesives

Improving the adherence of your bottom layer on the print bed may be sufficient to keep the corners from rising. Bed adhesion generally entails covering the bed with something sticky before beginning the print.

You can use many materials to stick your PETG to the print bed and keep those curling edges down. Most people use blue painter’s tape since it’s the easiest to pull off the bed and won’t leave a residue.

However, you can also use hair spray, which aids in establishing a good grip for most types of filaments. You may also use 3DLac, a specifically made 3D printing bed spray.

You may also use a PVA or regular glue stick. There are additional bed adhesion items, such as the Magigoo 3D Printer Adhesive from Amazon.

Any of these sticky materials should aid in the adhesion of PETG to the build plate. Whatever you pick, your build plate should only require a thin, even coating.

Change Your Slicer’s Settings

There are a few slicer settings that can help prevent warping and keep the print in place on the bed:

- Print more slowly. You’d be amazed how frequently slower print rates may aid in the resolution of the most challenging printing issues, such as warping and curling.

- In your slicer, make a brim or skirt. A skirt is a perimeter offset from the part’s edge, whereas a brim is one or more extra layers of outlines linked to the base’s edge. These supports offer your model a larger perimeter, which improves its grip on the construction surface.

- Add a raft. A raft expands the base of your 3D printed model and becomes the new first layer of your object. Rafts can make a fantastic foundation for your PETG prints since they stick well to print beds, but they should make it simpler to peel the model off. The only problem with rafts is that they may be challenging to remove from your print during post-processing.

- Add mouse ears. Mouse ears are little, two-layer discs that you print under your object to improve bed adherence on corners. To use them, you can place them on the print bed around the perimeter of your object. When your print work is complete, removing them from your model will be a piece of cake. You may get some ready-made mouse ears or print them yourself.

Print Bed Warping

Sometimes, you’ll see your print bed warping together with the print. Print bed warping is common with big objects (with broad initial layers).

This problem is most likely due to the enormous print accumulating significantly more warping pressure than usual. Although adhering well to the object, the flexible build plate bends with the cooling filament.

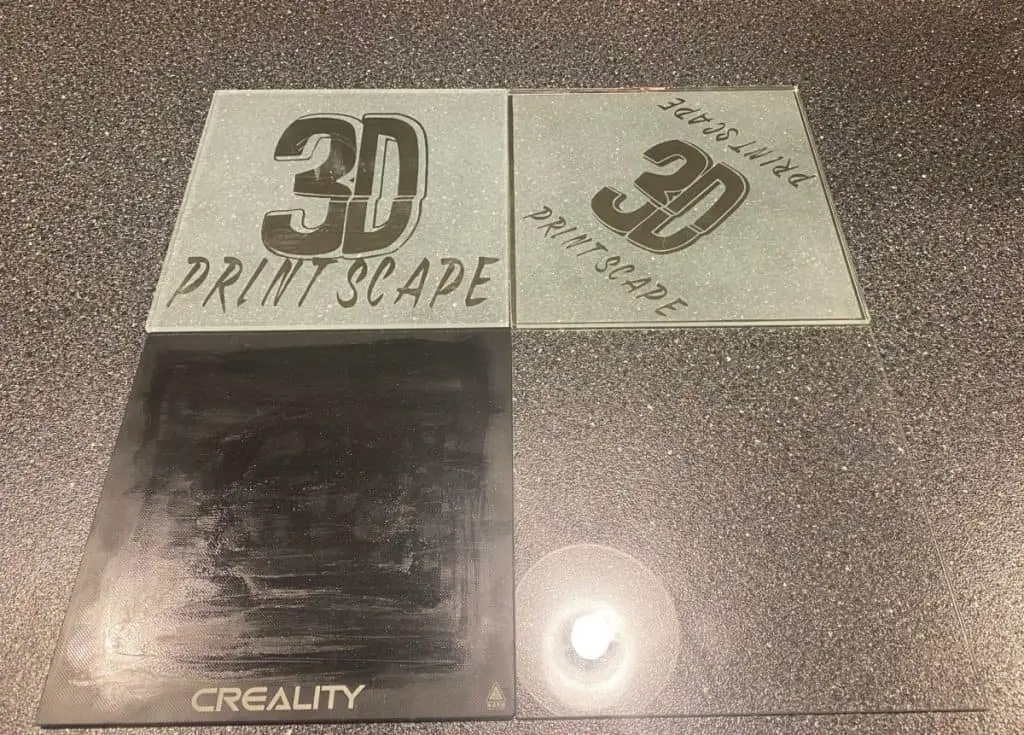

If you have this issue or are concerned about having it and cannot reduce it using the options listed above, consider switching to a glass build plate.

Related Articles

- Does PETG 3D Printing Create Toxic Fumes?

- All About 3D Printer Plastic

- Can You Drill Into and Cut 3D Printed Plastic?

- Can I Dry Filament in Microwave? (Details Inside)

Conclusion

PETG may be sensitive to warping at temperatures above 170°C (338°F). This article brought out a few tricks you can use to prevent this, including changing your slicer’s settings, using adhesives, and regulating the temperature of your printing environment. Hopefully, if you follow these tips, your next PETG print will have smooth edges, better layer adhesion, and a warp-free finish!

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.