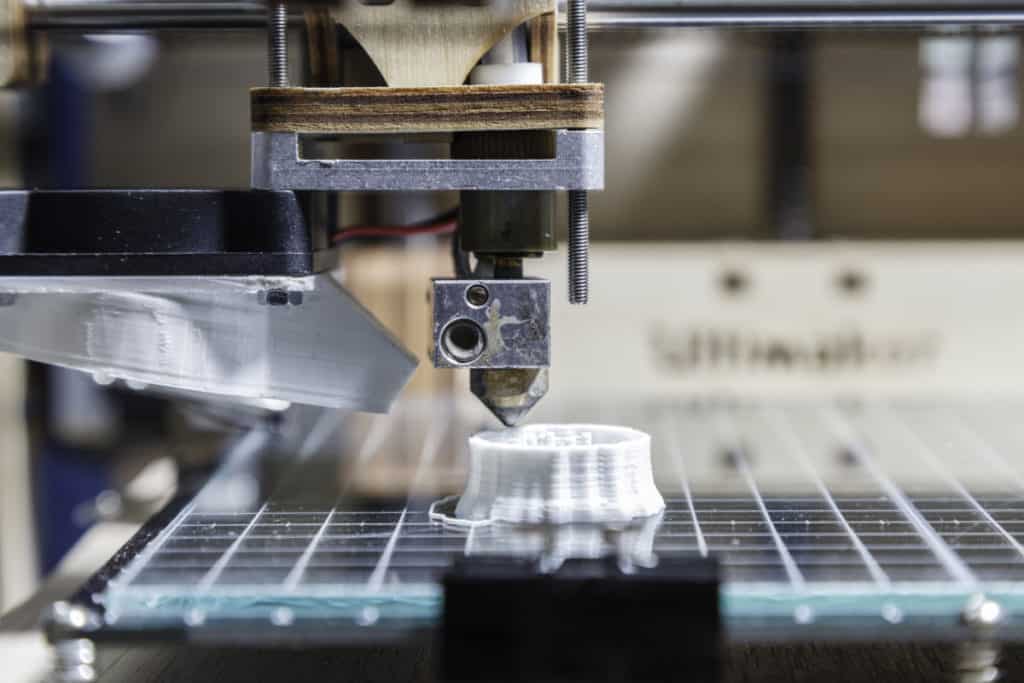

Fused Deposition Modeling (FDM) is a commonly used type of 3D printing. FDM 3D printers melt and expel thermoplastic filaments to construct three-dimensional designs. It prints a layer at a time, one on top of the other, to complete an incredibly complex composition. This process can take many hours to complete. And it’s not without fumes.

What are FDM printer fumes? In this process, the 3D printer releases fumes that emit from the melted plastic filaments. These fumes contain particles that could be potentially hazardous and damaging to one’s health.

When it comes to FDM printer fumes, what type of filament is used in the printer makes a difference as to how toxic and harmful the fumes may be to those who are in close proximity to them.

What Exactly Are FDM Printer Fumes?

FDM printer fumes are emissions accompanied by the unpleasant odor that you smell when you are using a 3D printer. Depending on which thermoplastic filament that you use, some are worse than others, in both odor and in regards to your health.

The fumes are emitted from the printer while it is melting and layering the plastics to create whatever object you are printing. There are a few common thermoplastics that are used when it comes to FDM 3D printers.

Two types of pollutants are found in printer fumes: Volatile organic compounds (VOCs) and ultrafine particles (UFPs).

VOCs

VOCs are organic chemicals that have a high vapor pressure at room temperature. Even VOCs that are particularly harmful don’t tend to be immediately life-threatening, but they may have detrimental long-term health effects. The research on VOCs is challenging because symptoms from them are slow to develop.

UFPs

Airborne particulate matter is mainly composed of UFPs. Their ability to deeply penetrate the lung makes them a large concern when thinking about FDM printer fumes, seeing as they can greatly affect respiratory health.

PLA Printer Fumes

Polylactic Acid (PLA) is widely considered to be relatively the safest thermoplastic filament to use in conjunction with your 3D printer. PLA differs from other thermoplastic polymers because it is derived from renewable sources such as cornstarch and sugar cane.

The odor tends to be much more pleasant than with other thermoplastic filaments and is much less hazardous. PLA filament particles contain lactide, which is deemed to be non-toxic and relatively harmless.

The exception to this harmlessness is in cases where it is heated above the temperature of 200°C. Prolonged exposure could still possibly cause some issues, so it’s always safe to limit your time inhaling the vapors.

ABS Printer Fumes

Acrylonitrile butadiene styrene printer fumes, on the other hand, have proven to be much more dangerous than PLA printer fumes.

Unlike PLA printer fumes, which contain a non-toxic chemical in the particles of the fumes, ABS printer fumes contain particles that consist of styrene. Styrene is presumed to be a carcinogen and can induce headaches, drowsiness, and fatigue in those who are exposed to it.

There have been recorded studies that show signs of damage to lung cells after exposure of as little as three hours to ABS printer fumes.

You may use ABS at your own risk, but from what studies have shown, it is definitely not the safest choice.

Nylon Printer Fumes

Nylon is a less common filament than PLA and ABS, but it is common enough to know the dangers when it comes to its fumes as well. They are on the same level as ABS printer fumes when it comes to toxicity.

The compound found in the particles excreted by Nylon printer fumes is called caprolactam, and it can cause eye and lung irritation.

Similarly to ABS, you should use at your own risk and invest some time in ways that will reduce the effects of the fumes.

Precautions When Using an FDM Printer

When protecting yourself from any ill effects that might happen following inhalation of FDM printer fumes, you should be sure that your printer is in a well-ventilated room and, preferably, one separate from a bedroom.

Where to Use Your Printer

Something to keep in mind is where you are using your 3D printer. If a printer is to run overnight and it is housed in or near your bedroom, this could lead to hours of breathing in the fumes, which could lead to harmful consequences to your health.

It is a smart idea to use your 3D printer in a room that is not only well ventilated but also might have a window that you can leave, weather permitting, while you are using the printer. Also, a room with a fan that you can keep running at the same time would be helpful to offset the fumes.

Even better would be a well-ventilated garage or studio space, away from living areas.

Air Purifiers

Another way to offset the fumes would be to invest in an air purifier. Many air purifiers on the market are not only able to neutralize any odors but also to filter some of the toxic elements that might be in the air. This would greatly improve the quality of the air even while you are printing with your 3D printer.

High-Efficiency Particulate Air (HEPA)

HEPA filters are made specifically to filter particles like UFPs, and though they won’t purify the odors or neutralize the VOCs, they are designed to remove 99.97 percent of particles of 0.3 microns in size or larger.

UFPs from 3D printers might be smaller (less than 0.2 microns), but oftentimes they clump together in the air to form larger particles, so the HEPA filter will still be effective in this situation. It has been found that when used with 3D printers, HEPA filters reduced UFP concentrations by up to 98 percent, making quite a difference.

Carbon Filters

Carbon filters are another option, which acts in the opposite way that HEPA filters do. They have no effect on the UFPs in the room, but they neutralize odors and capture the VOCs efficiently.

Carbon filters have a reputation of losing their efficiency over time, though and actually start to emit the captured odors and compounds back into the air that they filtered, so it is best to replace these very often if you choose to use one.

The best solution, if your budget allows, would be to use both a HEPA and carbon filtration system so that you may tackle both the UFPs and VOCs in terms of the toxic particles and gases that are in 3D printer fumes. It’s also not a bad idea to look at adding an exhaust system for your workspace.

Enclosed Chamber

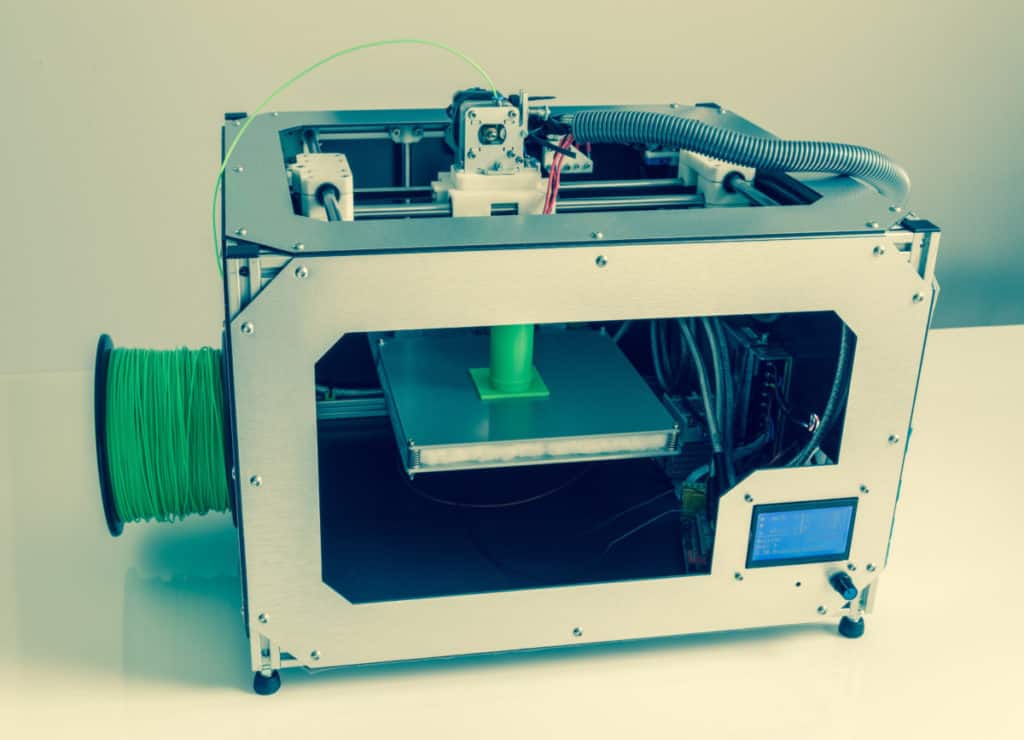

Many people find that the best way to deal with the fumes is to essentially trap it by keeping the 3D printer in a fully-enclosed chamber.

Should I Use an FDM 3D Printer?

FDM 3D printers are a fascinating line of equipment that can produce complex projects, but in doing so, need to be monitored closely for their toxic fume emissions, depending on what filament is used.

There are many options you can implement to protect yourself from these fumes so that you do not suffer from any health concerns from them, such as ventilating your room, opening a window, or buying an air purifier.

Don’t avoid this technology; just choose wisely where you’ll use it, how you use it and how often you expose yourself to the fumes.

There is not enough research done on how much is too much when it comes to breathing in the particles released with 3D printer fumes. So, it is best to remain on the cautious side and enjoy your new hobby!

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.